Suction and compression process The suction and compression of the injection pump is accomplished by the plunger reciprocating within the plunger sleeve. When the plunger is in the lower position, the two oil holes in the plunger sleeve are opened. The inner cavity of the plunger sleeve is communicated with the oil passage in the pump body, and the fuel is rapidly filled in the oil chamber. The plunger rises as the cam hits the roller of the roller body. Move upward from the beginning of the plunger until the oil hole is blocked by the upper end of the plunger. During this time, due to the movement of the plunger, the fuel is squeezed out of the oil chamber and into the oil gallery. So this lift is called pre-stroke. When the plunger block the oil hole, it began to pressure process. Plunger up, oil chamber pressure rose sharply. When the pressure exceeds the spring force of the oil valve and the upper oil pressure, the oil valve is opened and the oil is pushed into the oil pipe by the oil pressure.

The time when the oil inlet hole on the plunger sleeve is completely blocked by the upper end surface of the plunger is referred to as the starting point of the theoretical oil supply. Continue to move up the plunger, the fuel has been continued, the pressure process continues until the helical bevel on the plunger to open the plunger sleeve back to the oil hole so far, when the hole is opened, high pressure oil from the oil chamber by The longitudinal groove on the plunger and the oil return hole in the plunger sleeve return to the oil passage in the pump body. At this point the plunger sleeve oil chamber pressure rapidly reduced, the oil valve in the spring and high pressure tubing back to the valve seat, the injector immediately stop injection. At this point although the plunger is still up, but the oil supply has been terminated. The plunger oil return hole is opened by the hypotenuse of the plunger is called the theoretical end of the oil supply. In the plunger up the entire process, only the middle of the stroke is the process of pressure, this stroke is called the effective stroke of the plunger.

Fuel Level Adjustment To meet the diesel load requirements, fuel pump delivery must be capable of being regulated from maximum fuel supply (full load) to zero fueling (parking). Fuel supply regulation is through the gear rod, rotating sleeve so that all the fuel injection pump plunger rotation to achieve. When the plunger rotation, the fuel supply start time unchanged, and the end of the oil supply, due to the hypotenuse of the plunger sleeve back to the hole position change changed. With the different angles of rotation of the plunger, the effective stroke of the plunger is also different, so the amount of fuel supply also changes.

The greater the angle the plunger does not rotate the oil supply 1, the greater the distance between the upper end of the plunger and the hypotenuse of opening the oil return hole of the plunger sleeve, the greater the oil supply. If the plunger rotation angle is greater Small, the oil cut started earlier, the fuel supply is also smaller. When the diesel engine must be off when the oil, to this end, the longitudinal groove on the plunger can be turned directly to the plunger sleeve on the back hole. At this point, throughout the plunger stroke, the fuel in the plunger sleeve has been through the longitudinal groove, back to the oil hole back to the oil hole, there is no pressure process, so the fuel supply is equal to zero. When the plunger rotation, the use of change the end of the moment to adjust the amount of fuel supply, this method is called the oil endpoint adjustment method.

Fuel pump oil supply to meet the needs of diesel engines in a variety of conditions, that is, when the load increases for a large amount of fuel: load hour reduced fuel supply. At the same time also ensure that the fuel supply to each cylinder should be equal. According to the requirements of the diesel engine, the oil pump must ensure the same starting time of each cylinder, that is, the advance angle of each cylinder should be the same, and the same duration of oil supply should be guaranteed. Oil phenomenon. Depending on the type of combustion chamber and the method of forming the mixture, the pump must provide sufficient fuel to the injector to ensure good atomization quality.

More Search Keywords: Oil Pump

1. Thicken welded steel tubes, the thickness is at the top of CNC Router industry in China. The 4 X8 cnc router is the basic size, also available size of 5 X 10 cnc router, 6 X 10 cnc router etc size.

2. 3kw or more power HSD spindle or water cooling type. This one is with no maintenance, 6000-18000rpm.

3. The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

4. Taiwan rail linear bearing ,double slippers,bearing heavy,working steadily.

5. Stepper motors are motion systems allowing to have a high positioning precision. With their high power already at low speed, their stall torque and the possibility to divide the steps in microsteps, stepper motors can provide direct and precise motions in a small volume.

Specifications of SCT wood Engraver CNC Router:

Applicable Industry:

1. Woodworking industry:

Three dimensional wave plate processing, cupboard doors, wooden doors, window processing, vedio game cabinets and panels,Computer table and furniture auxiliary processing.

Advertising signs, logo production, acrylic, plastic cutting, production of decorative materials, forming system module, etc.

3. Furniture industry,

Solid wood furniture, solid wood doors, decorative materials, computer tables, panel furniture, office furniture, wooden.

Option:

1) Dust collector

2) Vacuum table

3) Rotary ( for engraving round objects)

4) DSP controller

| Model | SCT-W1325 |

| Work Piece size | 1300x2500x200 [mm] |

| Working Axes | 3 axes, Horizontal & Vertical |

| Machine Floor area | 3.5 [m]x 2.5 [m], |

| Work Piece clamping | Vacuum table |

| MainUsed Materials | Formica Topped plywood, 6-20 [mm] thick. MDF, 4-28 [mm] thick |

| Tools Replacement | Non-Automatic different Tools Can be used |

| Working Speed | 15000 [mm/m],min. |

| Rapid Travel speed | 30000 [mm/m], min. |

| Sawdust Removal | Required |

| Working Accuracy | ±0.05 [mm], min. |

| Repositioning Accuracy | ±0.05 [mm], min. |

| Working Power | AC220V/380V/50HZ |

| Software Capabilities | Artcam User Friendly, Supports English, 3D CAD format (STEP-), Optimization for maximal Raw material usage, quick set up. |

| Noise Level | 85 [db(a)] max,, 88 [db(a)] max, for short time operations only. Measured Within a: 40 [m2] x 2.5 [m] max. Space |

| Spindle | 3kw water cooling spindle |

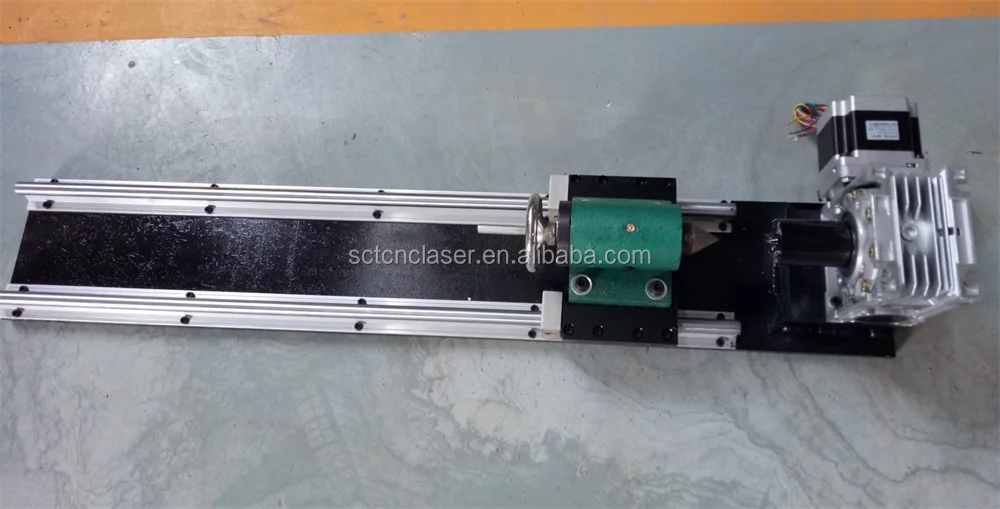

Rotary Axis for cylinder materials optional:

They are firstly greased thoroughly and packaged in a free-fumigation wooden crate. At SCT we strive to make your buying experience as convenient as possible. We work directly with shipping companies to ensure the best price for the shipment and we pass those savings on to you. Please notify salesperson at the time of your quote request if you wish to arrange for your own shipping method.

Guarantee

CNC Router–full 12 months back to base warranty on the router cnc and relevant manufacturers warranty on 3rd party add ons. This covers electrical and mechanical parts under `normal use`.

After-sales service

•Guarantee one year (except for consumable parts)

•Whole lifetime free service

•Technical support online or remote control

•Free tutorial and training courses (in video or in factory)

•Spare parts discount

CNC Router

CNC Router,CNC Wood Router,CNC Engraving Router,Small CNC Router

Shandong Sunrise CNC Machine Co., Ltd , https://www.scmcnc.com

没有评论:

发表评论